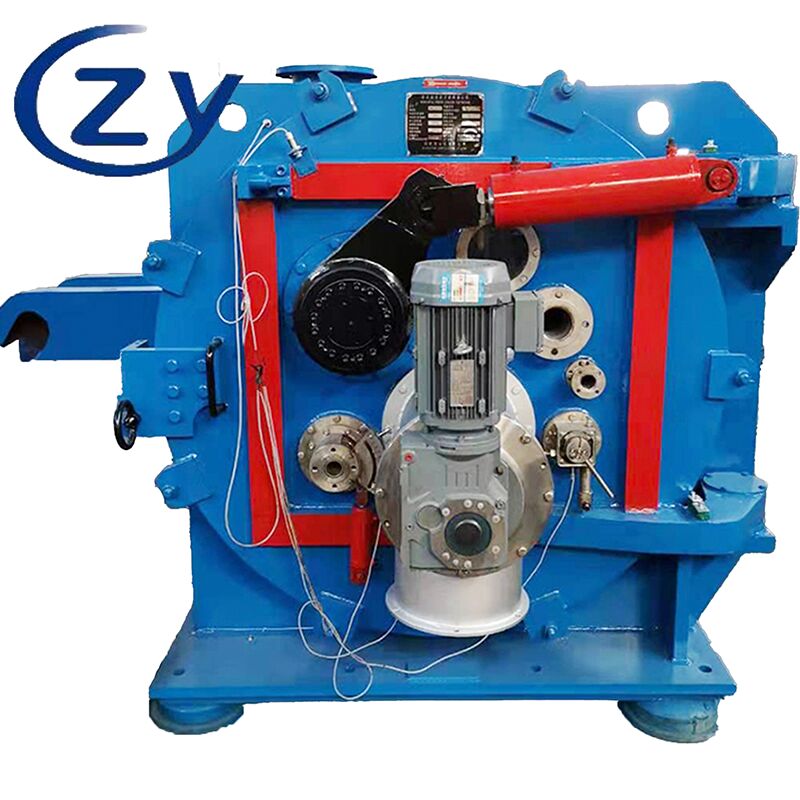

Centrifugadora de pelar de gran capacidad - Equipo de deshidratación para el estiércol de harina de yuca en las instalaciones de procesamiento de harina de yuca

Datos del producto:

| Lugar de origen: | Henan China |

| Nombre de la marca: | ZY |

| Número de modelo: | GK1250 |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 juego |

|---|---|

| Precio: | 50000 |

| Detalles de empaquetado: | caja de madera |

| Tiempo de entrega: | 2month |

| Condiciones de pago: | LC, T/T |

| Capacidad de la fuente: | 5 set un mes |

|

Información detallada |

|||

| Tamaño: | Personalizado según el tipo | Fiabilidad: | Alto |

|---|---|---|---|

| Nombre del producto: | Centrifugadora del raspador | Fuerza: | Eléctrico |

| Nivel de vibración: | bajo | Temperatura: | bajo |

| Capacidad: | Alto | Nivel de ruido: | bajo |

| Mantenimiento: | Fácil | Nombre del producto: | Centrifugadora del raspador |

| Función de la maquinaria: | Equipo de deshidratación de almidón. | Industrias aplicables: | Fábrica de alimentos y bebidas |

| Materia prima: | yuca, patata, batata | ||

| Resaltar: | Centrifugadora de pelar de gran capacidad para harina de yuca,Equipo de deshidratación para el estiércol de yuca,centrifugadora de raspador de decanter con garantía |

||

Descripción de producto

Centrifugadora de pelar de gran capacidad - Equipo de deshidratación para el estiércol de harina de yuca en las instalaciones de procesamiento de harina de yuca

Descripción del producto:

La centrifugadora siphon peeler se desarrolla sobre la base de la centrifugadora peeler estándar.Utiliza un sifón para aumentar la fuerza que empuja el líquido clarificado a través del medio de filtración en la cámara de líquidoLa posición del tubo de sifón puede alterar el nivel del líquido en la cámara de succión, regulando así la fuerza de filtración.velocidad, el rendimiento, la sequedad del pastel sólido y la eficiencia de limpieza.

Características:

- El funcionamiento totalmente automatizado reduce la intensidad del trabajo manual.

- Una estructura completamente cerrada ofrece un entorno de operación óptimo.

- Todos los componentes de accionamiento dependen de sistemas hidráulicos para el control automático, garantizando un funcionamiento constante y fiable.

- El sistema eléctrico está equipado con control PLC, con movimientos precisos y un ajuste sencillo.

Parámetros técnicos:

| Parámetro | Valor |

|---|---|

| Nivel de ruido | Bajo |

| El poder | Eléctrico |

| Tamaño | Personalizado según el tipo |

| Confiabilidad | En alto. |

| Mantenimiento | Es fácil. |

| Temperatura | Bajo |

| El material | Acero inoxidable |

| Nivel de vibración | Bajo |

| Capacidad | En alto. |

| Aplicación | Separación de sólidos de líquidos |

| Máquina automática de deshidratación | - ¿ Qué? |

| Centrifugadora para pelar al almidón | - ¿ Qué? |

Aplicaciones:

Ámbito de aplicación

Ampliamente utilizado en industrias como la ingeniería química, procesamiento profundo de granos, alimentos, productos farmacéuticos e industria ligera.

Personalización:

- Nombre de la marca: ZY

- Número de modelo: GK

- Lugar de origen: Henan, China

- Temperatura: baja

- Nivel de vibración: bajo

- Nivel de ruido: bajo

- Aplicación: Separación de sólidos de líquidos

- Durabilidad: Alta

- Características especiales: Máquina automática de deshidratación, centrifugadora de exfoliación

![]()

Preguntas frecuentes:

- P: ¿Qué es la centrifugadora de raspadores de decanter?

- R: La centrifugadora de raspador decantador es un tipo de separador centrífugo producido por ZY con número de modelo GK, que es de Henan, China.

- P: ¿Cuáles son las características de la centrifugadora Decanter Scraper?

- R: La centrifugadora de raspadores de decantador tiene una alta eficiencia de separación, bajo consumo de energía y una gran capacidad de producción.

- P: ¿Son los materiales de la centrifugadora Decanter Scraper seguros?

- R: Sí. La centrífuga de raspador de decantador está hecha de acero inoxidable de alta calidad, que es seguro y duradero.

- P: ¿Cuál es la aplicación de la centrifugadora de raspador de decantador?

- R: La centrifugadora de raspadores de decantador se utiliza ampliamente en la separación y clarificación de materiales en la industria química, farmacéutica, alimentaria y otras industrias.

- P: ¿Cuál es el período de garantía de la centrifugadora Decanter Scraper?

- R: El período de garantía es de un año desde la fecha de envío.